How It Works

Potlining is a crucial step to maximize the life of pots. Ramming paste needs to be homogeneously compacted between the cathode blocks and at the pot walls to avoid infiltration and premature failure of the potlining.

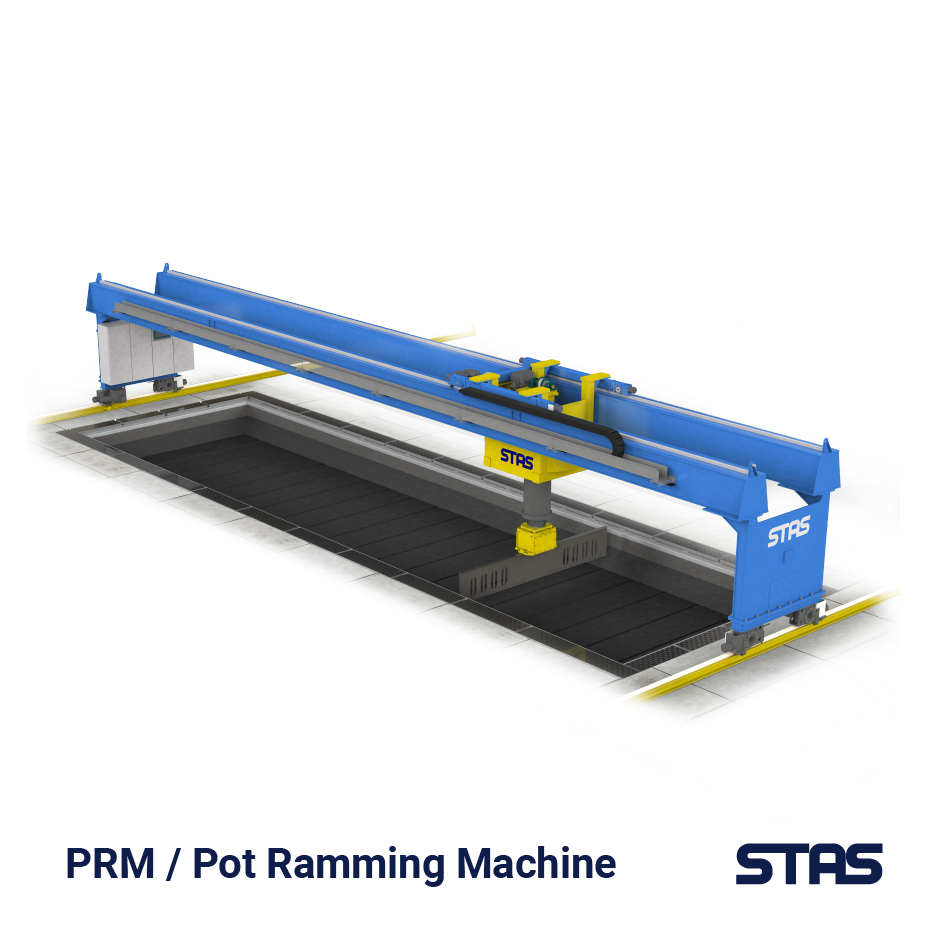

The new STAS pot ramming machine is the result of a thorough development process. The machine uses the proven vibrocompaction approach in accordance to the standards of pot technology suppliers. The patent pending compactor ram is designed to move the compaction tool in a perfectly vertical trajectory, which will ensure uniform compaction while greatly facilitating the operation.

Key features

Adaptable to all pot technologies.

Optimized isolation for reduced transmission of vibration and noise.

- Fully adaptable production recipe according to pot technology and customer practices.

Very slim design to provide maximum visibility to operators.

Measured noise level below the recognized industry standards.

Simple and robust design for low maintenance requirements.

Tunable dynamic and static loading to extend compaction capabilities and flexibility.

Enough ground clearance to allow the machine to move to another pot without the need for an overhead crane.

Sophisticated quality control system with real-time, automatic compaction measurement.