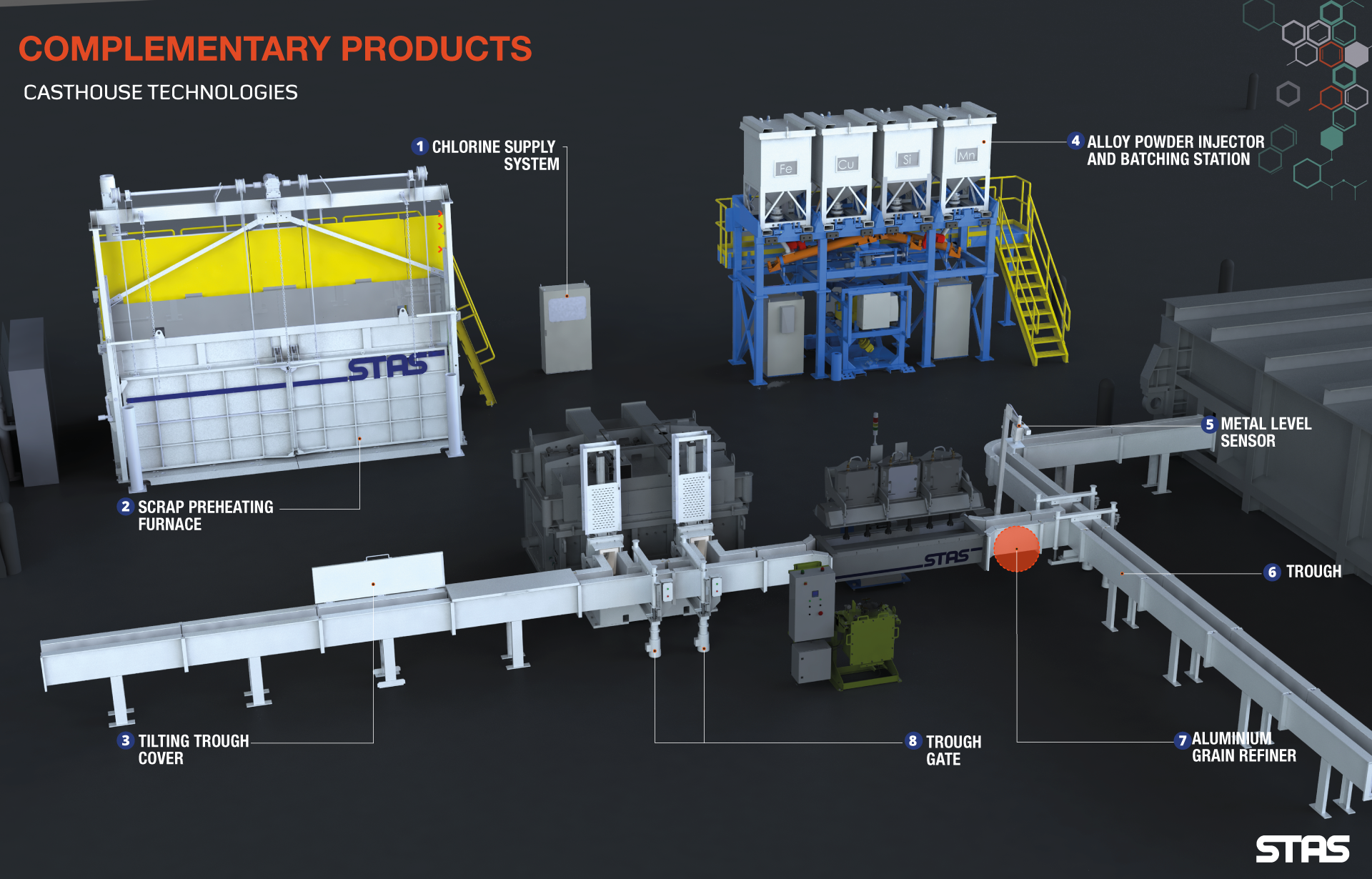

Here are some of the products we can design and manufacture:

1-Chlorine supply system

- Specially designed panel

- Weighing system

- Valves and sensors

- Dedicated controller

- Field chlorine detector

- Optional automatic shut-off valves

- Optional chlorine scrubber

2-Scrap preheating furnace

This furnace is designed to remove all traces of humidity and/or water that may be present on the surface or inside the materials to be loaded inside. It use convection to quickly transfer the heat and ensure a uniform temperature level inside.

- Electrical or gas

- Fully customizable dimensions

3-Tilting trough cover

Tilting cover is mainly used to minimize heat loss during cast but also used to preheat the refractory prior to casting.

4-Alloy powder injector and batching station

The batching station is mainly used to correctly dose the amount of powder required according to the desired “recipe” and to route it to the injection bell (injector).

The injector will inject the powder into the furnace – nitrogen is used to convoy the powder into the liquid aluminium.

5-Metal level sensor

The laser distance sensor is complete with a stainless steel insulated box and structural support ready to be bolted or welded to the customer’s trough. Upon request the metal level sensor might come with a vortex cooling system, including a thermocouple and a solenoid valve.

6-Trough

This section connects the furnace to the casting machine as well as the degasser and the filtration system. Some design criteria are important in this:

metal flow rate, width, depth and the type of refractory material used.

7-Aluminium grain refiner

Grain refining is a key factor in melting and solidification processes of aluminium alloys. Addition of grain refiners to molten aluminium alloys reduces aluminium grain size and improves fluidity, allowing faster casting speeds, and a better homogeneity and uniformity of the structure of the alloy. Our grain refining technology with continuous grain refinement and alloying provides a number of technical and economic advantages.

8-Trough gate

It is necessary, on a through line, to have barrier systems to control the metal level in the trough. These barriers are used, in the majority of the cases, at the beginning of the casting and / or at the end. These can be moved manually or via a different mechanism (electric, pneumatic, etc.), all of which we can provide individually.