How it works

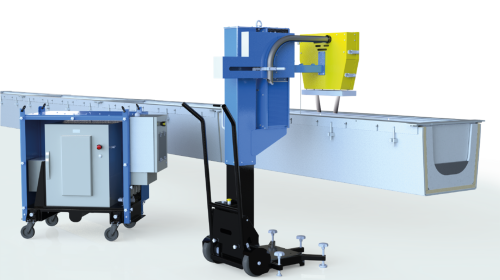

The BATSCAN® is a continuous inclusion monitoring system that can be positioned in the trough at any point between the furnace and the casting pit.

The system is designed to measure inclusion levels in the molten metal using ultrasounds through a transmitter and a receiver (waveguides) immersed in the liquid metal.

Measurement principle

• In-line measurement directly in the trough.

• Continuous immersion in the melt.

• Measures variations between emitted and received ultrasounds caused by particles present in the melt.

• Continuous acquisition of the signal.

• Automated post-treatment after the acquisition period.

• Post-treated file provides ultrasonic intensity signal versus time for different ultrasonic thresholds.

Key features

Metal Quality Measurement Efficiency

- High sampling volume (2% of the whole cast volume).

- High measurement frequency (inclusions are tracked every 0.1 sec).

- Ready to measure in a very short time (typically 15 sec).

- Patented technology embedded to cancel bubble interaction with the waveguides hence stabilizing signal sensitivity.

- Key measurement positions targeted by the BATSCAN®, particularly at the filter or furnace outlet.

Productivity Improvement / Operating Cost Efficiency

- Very low operating and maintenance costs (no consumable parts thanks to the use of non-reactive ceramic).

- Compatible with all aluminium alloys.

- Not sensitive to electromagnetic interferences (induction furnace, electromagnetic casting).

Safe Operating Environment

- Automated operation (option available with fixed BATSCAN® only)

Other compatible equipment – Metal treatment and casthouse technologies

Metal treatment and casthouse technologies