How It Works

Metal and bath crucibles are regularly cleaned, repaired or rebuilt with a new refractory lining before they are returned to service. Whatever the reason for maintenance, it is important that the lining of those crucibles be safely dried and preheated.

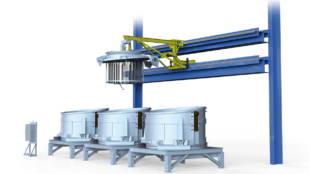

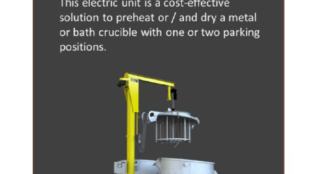

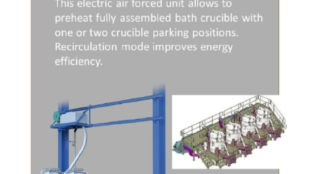

STAS has developed several types of preheating systems, either electrical or with gas, in order to meet the specific requests of its customers. The ACP / Aluminium Crucible Preheater totally controls the whole heating cycle, which ensures more uniform heating distribution before the first time molten metal is poured, hence a considerable reduction in energy costs.

“The Proven Technology to Preheat and Dry

Bath and Metal Crucibles.”

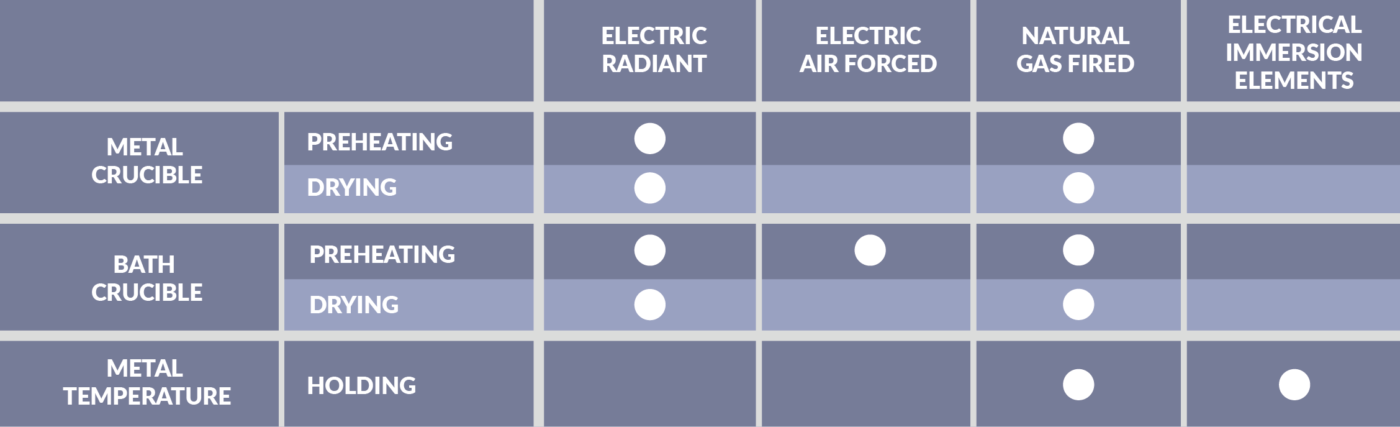

Types of crucible heaters

FOR CRUCIBLE PREHEATING

Before filling them with molten metal or bath, cold crucibles need to be preheated to avoid moisture entrapment.

FOR CRUCIBLE DRYING

When both metal and bath crucibles need to be relined with new refractory material, it is important that the new refractory material be properly dried before putting the crucibles back into service following a programmed ramp and soak determined by the refractory supplier.

FOR METAL TEMPERATURE HOLDING

When molten metal cannot be transported normally, it could be required to maintain or increase its temperature.

Key features

Productivity Improvement

- Uniform heat distribution.

- Meet requirements imposed by refractory manufacturers.

- Increased refractory lifetime.

- Fully automatic operation of the system.

- Possibility of integrating a monitoring to supervise and report heating condition of each crucible.

Some configurations allow preheating and drying.

Cost Improvement

Reduced energy costs.

Low operating, maintenance and capital costs.

The operator is not required during the preheating step.

Safe Operating Environment

The operator is away from any source of danger.

Noise level (for gas system) are below 85 dBA.

Other compatible equipment – Crucible shop