How it works

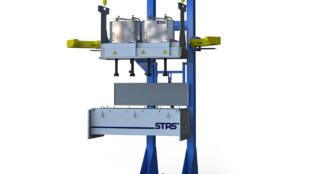

The ACD / Aluminium Compact Degasser® is a multi-stage, sealed in-line rotary degassing equipment that processes molten aluminium using spinning nozzles directly in the casting trough between the furnace and the casting pit.

The ACD is much smaller and flexible than conventional in-line degassers (with refractory‑lined steel boxes). Although the physical, mechanical and operational differences between the ACD and conventional degassers are significant, the underlying metallurgical principles involved in metal treatment are the same. The metallurgical performance of ACD is therefore equivalent or even superior to conventional degassing equipment.

Since there is no metal hold up in the machine at the end of a cast, alloy changes are much easier, and no heating is required. Then, the operating and maintenance costs of the ACD are lower than for any other type of degasser on the market.

The ACD is particularly effective for applications such as batch casting or when multiple alloy changes are required.

Key features

Metal quality improvement

- High hydrogen removal efficiency.

Good alkali and inclusion removal efficiency if chlorine or flux are used.

Productivity improvement

Operates in sealed mode; very little dross formation.

Eliminates metal loss due to alloy changes; furthermore, no need to remelt aluminium.

Eliminates the need to maintain molten aluminium between casts in the degassing chamber.

Operator‑friendly, easy to operate, fully automatic operation.

Low floor space required for installation (several models available)

Low Operation and Maintenance Costs

Eliminates high costs heating elements and thermocouples.

Eliminates high costs for replacement of refractory lining.

Reduces energy consumption.

Over 60% reduction of overall operations and maintenance costs.

Safe Operating Environment

- Elimination of chlorine, if required, through the use of the FFD / Flux Feeder for Degasser®.

Other compatible equipment – Metal treatment and casthouse technologies

FFD / Flux Feeder for Degasser

Metal treatment and casthouse technologies