How it works

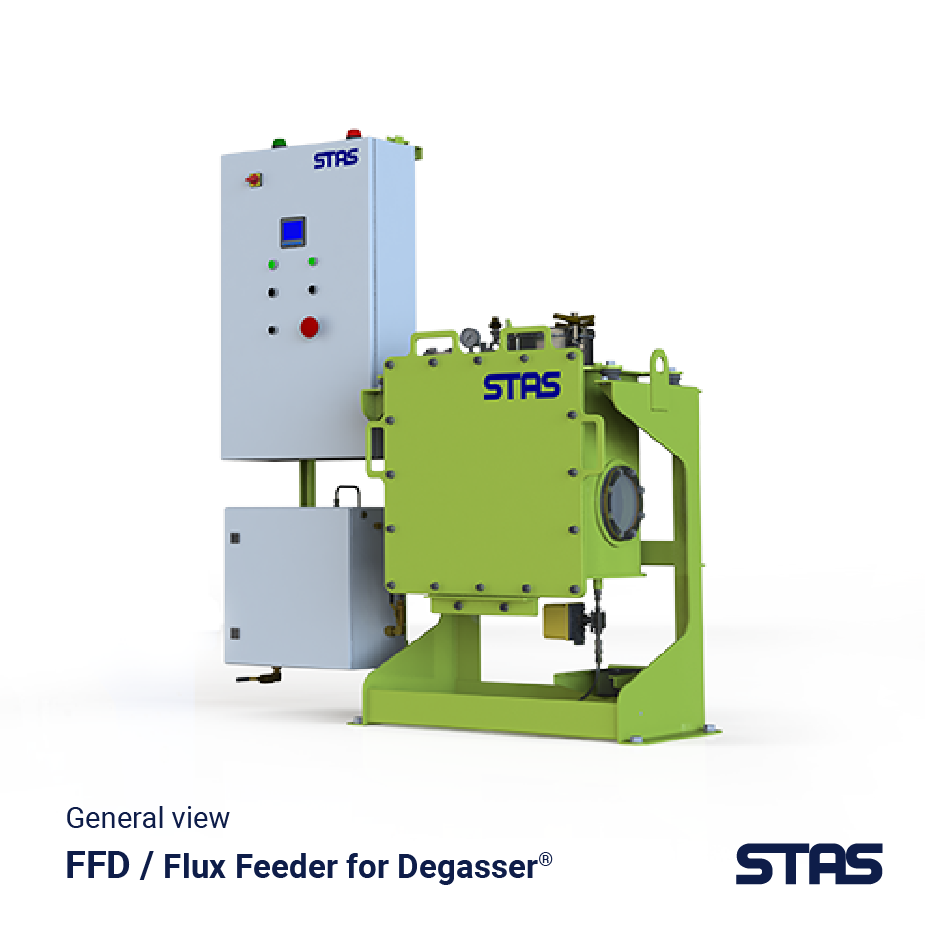

The use of chlorine gas to treat liquid aluminium and ensure its quality has long been a preferred method in the aluminium industry. However, because of the health, safety and environmental effects of chlorine, aluminium producers are increasingly inclined to stop using it, but this controversial gas is still used with some technologies such as degassers and refiners. There is now a new technology that provides a cleaner and safer treatment method: the FFD / Flux Feeder for Degasser, used to completely eliminate the use of chlorine in the casthouse.

The FFD, working in conjunction with the ACD or the AIR, allows to substitute a flux for chlorine. With this proven technology, the flux is injected through rotors of the treatment equipment and dispersed into small droplets in the liquid metal, where they are further sheared by other rotors. The flux is injected at a rate set according to the casting parameters (flow of liquid metal, type of alloy, metallurgical requirements, etc.).

It is now possible to completely eliminate the use of chlorine gas in the casthouse – and, at the same time, all of its negative impacts on health, safety and the environment – without compromising the quality of the metal.

A final point in favor of the FFD technology is that it is designed to easily retrofit ACD and AIR systems including all box-type models.

Key features

Metal Quality Improvement

- No negative impact on hydrogen removal.

- High alkali removal efficiency.

- High inclusion removal efficiency.

Productivity Improvement

- Operator‑friendly, easy to operate, fully automatic operation.

Safe Operating Environment

- No need for chlorine or a chlorine supply system.

- Reduction in fugitive and atmospheric emissions.

- Safer operation.

Other compatible equipment – Metal treatment and casthouse technologies

AIR / Aluminium In-line Refiner

ACD / Aluminium Compact Degasser

Metal treatment and casthouse technologies