How it works

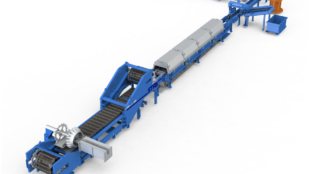

The ICS / Ingot Casting and Stacking has the ability to cast both pure Aluminium ingot and foundry alloy ingots on a continuous basis. The fully automated ICS can cast up to 32 tonnes per hour, pushing your production goals to their full extent.

Long lasting and durable casting chain and moulds maximize the operational life of the ingot casting system. Its electrical automation control system controls every step of the entire ingot production process.

Key features

CASTfill pouring Wheel

The pouring system directs metal into the ingot mould in a streamlined manner with minimal turbulence or splashing.

This ensures oxide levels are kept low, resulting in superior quality product with an attractive surface finish.

Up to 32 tonnes per hour operation.

Lower oxide levels coupled with a better finish.

Produces uniform ingot weight.

Developed using state-of-the-art computer simulation techniques.

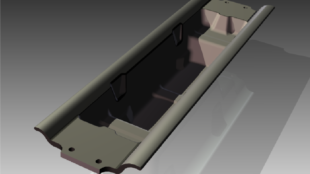

CASTmould

The CASTmould has been developed by o.d.t. Engineering and a team of research professionals to improve production rate, achieve longer service life and improve safety and performance by focusing on the following objectives:

Improved solidification rate.

Minimization of localised boiling of cooling water.

Better release of ingot from mould.

Less shrinkage and formation of cavities on the ingot surface.

Stacking

At the completion of the process, the machine’s stacking unit automatically packages and straps ingots into compact stacks that are suited for safe and easy transportation. The automatic robotic stacker, layering device and stack compactor form compact, integrated ingot stacks.

- A variety of configurations are available to perfectly suit your plant’s for stack storage, vehicle flow and transport requirements.

- The automatic ingot stack strapping system coordinates high production rates and provides reliable and safe stack strapping processes.

- The modular design offers easy equipment accessibility and maintenance.

Other compatible equipment – Metal treatment and casthouse technologies

Metal treatment and casthouse technologies