How it works

Aluminium production requires furnace fluxing or treatment to remove impurities. In order to meet quality requirements, dissolved alkalis like sodium and calcium, non‑metallic inclusions and hydrogen need to be removed. Furnace fluxing is still used either by spreading solid flux on the metal surface or using fluxing lances (chlorine). These methods can be replaced by the RFI / Rotary Flux Injector®, which uses salt mixtures to significantly improve the efficiency of the fluxing process.

The main element of the STAS RFI is the rotor, through which a carrier gas (nitrogen) delivers the fluxing agent (solid salts) underneath the metal surface. The liquefied fluxing agent is dispersed through the combined actions of the rotor and the injection of the carrier gas.

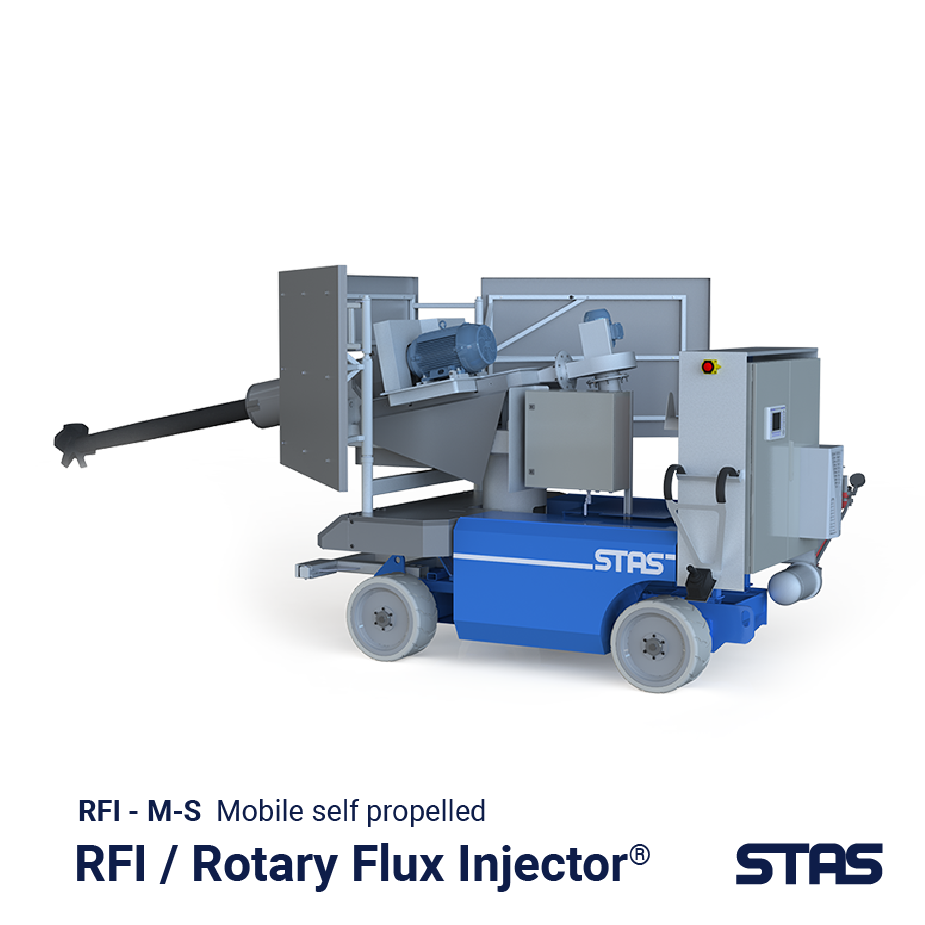

Since every plant and even every furnace are of different sizes and shapes, several models have been developed and adapted to meet any type of layout constraints.

Key features

Metal Quality Improvement

- Optimum efficiency of alkali removal (sodium, calcium).

Improves metal cleanliness (inclusion reduction).

- For RGI and RFGI, agitation phase made with argon after fluxing helps reduce hydrogen

Productivity Improvement

High stirring efficiency for metal homogenization (alloying and temperature).

Reduces dross generation.

Increases furnace productivity.

Safe Operating Environment

Elimination of chlorine.

Reduction in fugitive and atmospheric emissions.

Safe operation for employees.

Other Version/Option Available

- The RGI / Rotary Gas Injector® uses the same technique as the RFI but with chlorine fluxing instead of salt fluxing. However, less chlorine is used than with the lance technique.

- The RFGI / Rotary Flux and Gas Injector allows flexibility to use flux or gas process depending on production constraints.

Other compatible equipment – Metal treatment and casthouse technologies

Metal treatment and casthouse technologies